LEXICON

Abbreviations in cable technology

Y = Polyvinyl chloride

2Y = polyethylene

02Y = Polyethylene, chemically foamed

02YS = Polyethylene, physically foamed with skin

9Y = Polypropylene

11Y = Polyurethane

12Y = Polyethylene terephthalate ester

14Y = Thermoplastic elastomers

H = Thermoplastic elastomers halogen-free

LS = guiding layer

X = Networked

C = Braided shielding

D = Swirl screen

F = Foil

Vl = fleece tape

St = Static screen (Metallized composite film/metal foil, etc.)

Li = stranded wire

CuLi = Copper stranded wire

CuDr = Copper wire

B = coverage (related to a braid or swirl screen)

Tg yarn = carrier yarn (for fillers e.g.: EC-9 or EC-13), see also Cable Catalogue –> Technical Annex –> Abbreviations

Abrasion resistance is an important criterion for the service life of a cable. The abrasion is given as A [mm³]. Determination: A test specimen is guided with a specific contact force on a rotating roller covered with a test emery sheet. The total friction travel is approx. 40 m. The abrasive wear (loss of mass) is measured. The specification is made as volume loss in mm³.

AC

The ACR (Attenuation to Crosstalk Ratio) value indicates the relationship between near-end crosstalk and attenuation at a given frequency. An important factor for the transmission quality is the distance between the wanted signal and the interfering signal. To ensure proper transmission, the interference signal caused by the crosstalk attenuation must be smaller by a certain factor. This corresponds to the difference between the crosstalk attenuation and the attenuation of the cabling link. The interference signal originates on the one hand from the crosstalk of neighbouring lines and on the other hand from external EMC influences. With shielded cable, however, the external influence is so small that it can be neglected. However, with unshielded cable, adjacent signal lines can have an additional negative influence on the ACR.

Conductor with insulation as part of a single or multi-core cable.

![]()

Dader = Diameter core[mm] / Dlitze = Diameter strand [mm] / Wd-norm = Wall thickness, defined by standard or customer request [mm] / Dtol = Tolerance of the diameter of the production [mm] / Dzuschlag = Surcharge e.g.: for strangulated strands, wall thickness necessary for production.

Asociacion Espanola de Normalizacion (Spain), certification body.

Informal name of a digital audio standard created jointly by the AES (Audio Engineering Society) and EBU (European Broadcast Union) organizations. The standard defines the transmission characteristics of the digital signal to simplify communication between devices.

An aluminium alloy (AlMgSi) for conductors of higher mechanical stress (higher tensile strength). Aldrey is often used for aerial cables or overhead lines.

The course of aging of a cable depends on many factors – temperature – microorganisms – level of exposed voltage. Particularly in the case of coaxial cable lines, ageing also plays a role with regard to the electrical values. Corrosion of the braids, caused by plasticizers from the PVC compounds migrating into the dielectric of the core, and water vapor permeation, for example, play a major role. The resulting increase in attenuation only becomes noticeable at frequencies > 1000 MHz.

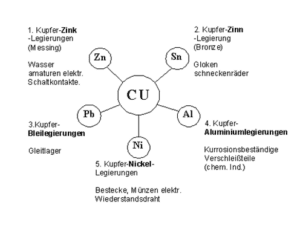

A few years ago, the raw material situation forced the cable industry to replace copper with aluminium. However, if the copper conductor is replaced by an equivalent aluminium conductor, the latter weighs only about half as much as the copper conductor, even though it has 1.6 times the cross-section. However, the larger cross-section requires increased material consumption of all downstream components such as the sheath and protective sleeves. Aluminium as a conductor material for cables and wires complies with DIN 40501. In terms of its importance as a conductor material, aluminium is second only to copper in electrical engineering and has so far only proved its worth in overhead line construction due to its low weight.

Amorphous refers to the irregular distribution of molecules, it is in the microscopic range the shapeless arrangement of the molecules of chemical substances. Amorphous (Greek = without shape) is the term used for plastics whose molecules are not arranged in regular crystal lattices, in contrast to crystalline.

American National Standards Institute. Committee in the USA which, similar to the German DIN, develops standards.

Are combined from the different power supply and media supply systems. Work areas are combined with the various workstation equipment and special accessories such as rail systems, jibs, tool carriers, cable reels, hose reels, balancers, hoists and tools. Flat and round cables with and without strain relief are used for workstation systems.

Arrhenius law says that for a temperature increase of 8 – 10 Kelvin, the rate of aging doubles. The following have an influence on the service life: – water treeing – thermal decomposition – migration – electrical ageing – chemical ageing.

Actuator Sensor Interface. ASI is not another fieldbus cable, but is specially designed for the exchange of information between sensors and actuators. It occurs as an unshielded two-wire line for the simultaneous transmission of signals and supply energy. ASI does not want to link controllers with each other but couples sensors and actuators to programmable logic controllers (PLC), numerical controllers (NC) and PCs.

American Society for Testing and Materials (USA), international standardization organization

Elevators for transport and industrial buildings. Product areas: Passenger elevators, bed elevators, glass and panoramic elevators, freight elevators, construction elevators. Depending on the application, combination cables are used for modern transmission systems. These control lines may include audio, video, telephone, emergency call systems, bus systems, etc. Each elevator manufacturer uses special cables made for them. Legal standards and regulations must be complied with for all product areas.

Propagation speed is the speed of transmission of electrical energy in a length of cable, compared with the speed of light in free space.

Conductive layer of non-metallic and/or metallic material covering the insulation.

One or more non-extruded layers on the outside of a cable.

American Wire Gauge is a coding for wire diameters and is mainly used in North America. It identifies electrical cables made of stranded and solid wire and is used primarily in electrical engineering to designate the cross-section of cores. The smaller the AWG number, the larger the conductor cross-section.

Baking enamels are applied successively to the same wire, as in the case of two-layer enamelled wires, with the lower layer, the insulating layer and the upper layer (baking enamel layer) being thermoplastic. This results in caking of the wound coil. Additional impregnation of the coil is unnecessary.

Bandwidth is the frequency range of a fiber optic cable in which data can be transmitted in a certain time unit. The larger the bandwidth, the more data can be transmitted. The transmission speed depends on the bandwidth of the entire network.

Taping is the process of wrapping pairs of conductors, stranding, etc. with fleece, plastic film, steel tape or other materials.

British Approvals Service for Cables (certification body for Great Britain and Ireland)

Unit for a step rate in the transmission of messages. One step per second.

Non-insulated wire in contact with a conductive layer or shield.

Ten decibels = 1 BEL. Bel, like decibel, is a dimensionless numerical ratio and is the unit of measurement for attenuation commonly used in high frequency engineering.

The travel speed in m/sec is a relevant parameter, especially for conveyor lines and trailing cables. However, customers often specify the performance of the cables to be offered in terms of (G) or the acceleration due to gravity. To make a conversion from G to m/sec².

Operating voltage is the voltage of an electrical circuit in volts which is necessary for its operation. It is the actual voltage in a network. It can fluctuate by approx. 5% due to changing use of current collectors.

Metallic sheath made of strips or wires, generally used to protect the cable against external mechanical stresses.

Conductors made of metal in which the wire or the individual wires are not coated with an additional metal (surface finishing)

Hydrocyanic acid (= hydrogen cyanide) is a colourless to slightly yellowish, flammable, volatile and water-soluble liquid.

The fire load is the energy released when wires and cables burn. It is described under VDE 0108, part 1 and the data sheets Fire load (unit kJ/kg)

Test to determine the fire behaviour, differentiated in categories A, B and C depending on the total volume (litres)

Describes the fire behaviour of a cable, a distinction is made between: Non-flammable, flame-retardant, normal-flammable and easily flammable.

The elongation at fracture is a material characteristic value which indicates the permanent elongation of the specimen after fracture, related to the initial gauge length. When a cable is bent, the surfaces of the insulating sheaths and jackets are stretched. When bending around its own diameter, which is not normally the case, the elongation in the outer phase does not exceed 50% and is thus far below the minimum permissible elongation of e.g. PVC. PUR has an elongation at break of approx. 500 %!

The breaking load is the product of the nominal cross-section and the tensile strength.

A “bus” is the combination of a large number of parallel lines to which several function blocks or components of a computer are connected. By using bus technology, cost savings of approx. 40% can be achieved for cabling, commissioning and maintenance compared to conventional technology.

| Short-form | Designation | Version | |

| UTP | Unshielded twisted pair | Pairs not shielded, no overall shield of the sheath | |

| S/UTP | Shielded – UTP | Pairs not shielded, total shield of the cable, not specified whether it is a foil shield or braided shield. | |

| FTP | Foil shielded twisted pair | Pairs not shielded, total foil shield of the cable | |

| S/FTP | Shielded FTP | Pairs not shielded, total foils and braided shield of the cable | |

| S/STP | Shielded twisted pair | Pairs with foil shield, total shield of the cable whereby it is not specified whether it is a foil shield or braided shield. | |

Butyl rubber is a synthetic rubber made from a copolymer of isobutylene and butadiene or isoprene. It has a high ageing resistance with low gas permeability and good resistance to chemicals.

Term for Community Antenna Television. CATV cables are primarily used for television distribution, but can also be used for all other transmissions up to 1 gigahertz.

Comitee for Electrotechnical Belgium Community (Certification body Belgium)

Canadian Electrical Code, abbreviation for the Canadian version of the National Electrical Code (NEC).

European Standards Institution, Commission on the Rules for the Approval of the Electrical Equipment.

Comité Européen de Normalisation Électrotechnique (European Committee for Electrotechnical Standardisation)

Chloroprene rubber is a synthetic plastic produced by the polymerization of chloroprene (chlorobutadiene). It has good solvent resistance with very good strength values, is flame retardant and acts as a thermal insulator, but is very expensive (high quality rubber cables).

Chlorinated polyethylene: Elastomeric sheath material, ozone resistant.

CMX is a type of the generic term communication cable according to. UL 444

CN is the abbreviation for cyanide. Cyanides are salts and other compounds of hydrocyanic acid, PUR is formed e.g. from the polyaddition reaction of diols or polyols with polyisocyanates.

Coating is a primary plastic layer applied directly to the cladding glass in fiber optics. It serves as a mechanical protective layer (sizing).

Abbr. CTI. The comparative number of creep path formation determined according to DIN/IEC is the numerical value of the highest voltage in volts at which a material can withstand 50 impingements of a defined test solution without creep path formation.

Abbreviation for polychloroprene, produced by polymerization of 2-chloro-butadiene.

Crimping is a mechanical connection technique. Here, when connecting e.g. coaxial cables with the corresponding plugs, a metal sleeve is pushed over the shielding by means of a crimping tool and squeezed together.

Canadian Standards Association (technical testing organization, Canada)

Attenuation is the line loss from the beginning of the line to the end of the line due to radiation of electrical power, since each conductor acts as a transmitting antenna. The smaller this value the better (reduction of the signal amplitude). The attenuation increases with increasing frequency and cable length, i.e. the signal level is degraded.

Generic term for the transmission medium of information and communication technology, e.g. cable, wire or optical waveguide that establishes the connection between transmitter and receiver. Today, the complete communication of trade and industry can be handled via data cables. The cabling routes are divided into classes A to E. The simplest data cables consist of two stranded copper conductors with a dielectric made of PE-foam-skin, for example.

See signal propagation speed.

Direct current

German electrolytic copper for conductive purposes. DEL is the exchange quotation for 99.5% pure copper in €/100 kg.

Danmarks Elektriska Materialkontroll, Denmark. State testing and certification body

Abbreviation: dB. Decibel is a dimensionless numerical ratio. It is the tenth part of a Bels and is the unit of measurement for attenuation commonly used in high frequency engineering.

Density is the ratio of mass to space of a body. If the mass is m and the volume is V, the density ratio is p = m/V.

The dielectric loss factor of an insulating material as a dielectric is the tangent of the loss angle by which the phase shift between current and voltage in the capacitor deviates.

The dielectric constant, indicates how many times larger the capacity of a capacitor with a certain insulating material as dielectric is, than the same capacitor with air as dielectric.

The DM quad corresponds to two stranded pairs while the star quad is layer-twisted. With this type of stranding it is possible, by means of suitable circuits, to conduct several calls simultaneously on the available wire pairs (phantom circuit).

Very tightly defined tolerances apply to the transmission properties of the conductor, which cannot be achieved with a stranded conductor.

A drop cable is the cable connecting the station to the network. This cable connects the station to the transceiver.

In this process, the wire is insulated in the injection moulding tool under pressure. A more or less large pressure component acts on the wire. This method is used wherever a pressure or force component acting on the cable during sheathing is permitted or desired. This is primarily the case with primary insulation where a certain adhesion of the insulation to the conductor is required.

Electrical spark discharge in which an insulation is destroyed, the current flows through the insulator. Here the voltage is higher than the dielectric strength of the insulation material.

In electrical engineering, the breakdown voltage, or flashover voltage, is the voltage which is necessary to allow current to flow through an insulation onto a metallic conductor. This results in electrical breakdown or voltage breakdown.

Thermosets are plastics with the property that they are initially deformable by heat treatment and can be irreversibly hardened by further heat treatment. The hardening is explained by a high frequency of cross-linking sites between the individual molecular chains.

Intrinsically safe cables (VDE 0165) for use in potentially explosive atmospheres. The cables must have a blue outer sheath as identification.

Assembly of support links connected with hinges for the directional, dynamic guidance of power cables of all types.

Single core cable with one concentric conductor provided as neutral.

Metallic wire of uniform cross-section used to make the conductor or shield.

Single wire with a thin metal layer to improve the properties or contactability (clad single wire).

Elastomers are elastically deformable plastics that deform under tensile or compressive load, but then return to their original shape. The serious difference between thermoplastics and elastomers is that the latter, as vulcanizates, do not have a melting point or melting range. However, this does not mean that elastomers are also stable at high temperatures. Here, too, thermal decomposition takes place, depending on the temperature and the duration of your exposure.

Electromagnetic compatibility. The term EMC is defined as the ability of an electrical device to perform an electrical function. device to function satisfactorily in an electromagnetic environment and not to influence other devices in an inadmissible manner. In this context, every electrical device must be seen simultaneously as a source of interference and as a sink for interference. The transmission of the fault takes place via the coupling. The line itself can be regarded as the actual source of interference. The generation of electromagnetic disturbances must be limited as far as possible so that radio, telecommunications, etc. can operate as intended. With suitable cable designs, interference signals can usually be minimized or shielded to such an extent that no negative effects are to be expected. The influencing factors are: – the optical coverage of the braiding – the braiding angle – the number of braiding wires – combination of braiding and St-screen and/or Cu-fleece. Parallel single wires or flat cables are the worst solution from the EMC point of view and should be avoided if EMC problems occur. The data line should always be laid separately and at the greatest possible distance from “interfering” power lines.

The cable drag chain is a component (assembly of hinged supporting links) in mechanical engineering that guides and protects flexible cables, pneumatic or hydraulic elements. Such cables are connected to a machine part which is constantly moved back and forth. Without such a guide, which guarantees compliance with the smallest permissible bending radius of the cables, the cables would quickly be destroyed under the continuous load.

Energy supply hoses are an ideal solution for standardized applications. Cables are fed into flexible round or flat profiles and fastened with appropriate adapters. For higher loads, a linkless and continuously extruded cable carrier profile is used. Noise and vibration free. Fields of application: Small overhead cranes, optical systems, stacker cranes, applications with a high degree of contamination, gate drives, handling technology, refrigeration technology. In addition to lines, hoses (water, compressed air, oxygen, fuel gases, etc.) can also be laid on. For robots, clean room use, chemical resistance, UV resistant, etc. Suitable for indoor and outdoor use.

Ethylene propylene diene monomer synthetic rubber is a terpolymer elastomer. Good resistance to ozone and ageing, very good electrical properties, cold-resistant, can be peroxide crosslinked. (Rubber insulated wires and cables).

Ethylene propylene rubber s. EPDM

Ethylene tetrafluoroethylene is a fluorinated copolymer, particularly suitable in wire-wrap technology. Mixed polymerization of ethylene and tetrafluoroethylene yields polyethylene-tetrafluoroethylene.

Ethylene vinyl acetate copolymer is a group of copolymers and is produced by copolymerizing ethene (ethylene) and vinyl acetate. EVA has a high heat and aging resistance for plastics.

Extrinsic losses are called the coupling loss of radiated power caused by insufficient or faulty connections.

Extrusion is the continuous melting of plastic moulding compounds and ejection through a shaping nozzle (die) in an extruder with subsequent cooling for the manufacture of semi-finished and finished products, e.g. cable insulation or sheathing.

Insulation generally consisting of a layer of thermoplastic or thermoelastic material applied in an extrusion process.

Abbreviation for Flat Core Flat Cable.

Fiber Distributed Data Interface: Interface for data transmitted via optical fiber. FDDI is a high-speed network technology based on the Token Ring. FDDI offers a transmission rate of 100 Mbit.

Spring cable reels with spring drive are used as power supply systems for mobile consumers of flexible power and control cables. Fields of application: Portal and slewing cranes, shipboard cranes, mobile cranes, construction cranes, loading systems, magnetic and grab cranes, electric trains, transfer cars, lifting platforms, forklifts, longitudinal scrapers in sewage treatment plants, charging systems, palletizing systems, storage and retrieval systems, also seagoing vessels, aggressive conditions, explosion-proof rooms, etc. The cable reels comply with the VDE and UVV regulations.

The fieldbus is a system of cables and connects field devices such as sensors and actuators in a plant for the purpose of communication with a control device.

see PTFE/FEP

High-precision round guide cylinder in which the glass fibre is inserted and fixed. Also wire end ferrule, for crimping flexible conductor ends; connecting single wires to screw terminals, spring-loaded terminals in electrical engineering.

The Fast Fourier Transform is an algorithm that mathematically expresses a process variable measured over a given time. In cable production, preferably in the manufacture of communication cables, the smallest cable parameter fluctuations must be avoided if they occur periodically. The production of state-of-the-art cable products (coaxial cables) requires constant monitoring of cable diameters, eccentricity and cable capacity with regard to periodic fluctuations. Online analysis of this measurement data in the frequency domain provides a powerful control tool for detecting periodic irregularities in cable extrusion.

Multicore cable that has cores or groups of cores arranged in parallel and flat.

Flame resistance describes the burning behaviour of wires and cables when exposed to flame. Only from oxygen index values of 27 are materials classified as flame retardant and even self-extinguishing. As an example, PE with an oxygen index of 17 burns like cotton.

Cable where flexibility in operation is required and whose construction and material are such that it meets these requirements.

Overhead lines are non-insulated conductor cables. Overhead lines are used for the overland transmission of electrical energy.

Since in this day and age the electr. As devices become more and more sensitive to interference and the number of devices generating electric fields is constantly increasing, it has become necessary to shield these interfering devices with regard to radiation of electric fields. A metallic screen is used here, which can be used either as a mesh or as a metal foil. Interfering impulses from outside to inside resp. inside to outside should be avoided by braiding.

A measure/indicator of braid quality

Multi-core cable that has a shield arranged concentrically to the cable axis around the cores.

Non-metallic sheath covering the stranded cores (including any gusset filling) of a multi-conductor cable and over which the protective sheath is applied.

The main advantages of foamed products are : – Smaller cable diameters with equivalent product properties – Lower material costs – Weight savings

Metallic sheath with generally annular or helical corrugations.

Insulation made of concentric layers wound helically around the conductor.

Distinction: Internal and external lubricants. Lubricants are preferably used as external lubricants to prevent sticking to the metal surfaces of the extruder. The surface gloss is also improved in the process.

Is a quantity derived from joules and kilograms. It indicates the absorbed dose caused by ionizing radiation and describes the energy absorbed per mass.

If two cable elements are to be mechanically separated, a force must be applied to a specified connection length of the elements, which can be measured. This specification in e.g.: N/100mm is called the interference fit.

Insulating materials should be free of halogens such as bromine, chlorine, fluorine and iodine. Halogen-free therefore means that a product as a whole does not contain such elements.

Hi-Pot: Insulation tests are performed with the Hi-Pot Station™ to ensure that there are no potentially hazardous leakage currents from the cell circuit to the exposed module surfaces.

High-frequency stranded wires are bundles of thin enamelled copper wires, which can consist of any number of individual wires.

A conductor constructed in such a way as to create a central channel.

Switching cores / switching strands

During prolonged storage in warm water, saturated steam or tropical climates, irreversible splitting of the molecular chains occurs in certain plastics.

s. Characteristic impedance

In electrical engineering, inductance is the inductive reactance or also the inductive alternating current resistance.

Non-metallic sheathing generally applied under a metallic sheathing, pressure protection or reinforcement.

Conductive layer of non-metallic and/or metallic material covering the conductor.

Interface, transition point between different hardware units

Insulating materials put up a very high resistance to the flow of electric current. It is inversely proportional to the cable length. Insulation resistance is a measure of the quality of the insulation material between two conductors or between a conductor and the shielding . The insulation material essentially determines the insulation resistance. It is not so much the insulation thickness that is decisive, but the material properties. The insulation resistance depends on the length, it is given in c. Its values should be 1 GOhm x km. Due to the length dependence, the insulation resistance decreases with increasing distances.

Assembly consisting of one or more cores, the individual sheaths of which, if any, may be – screens, jackets and armouring, if any – protective sheaths, if any. Additional uninsulated conductors may be integrated in the cable.

The insulating materials surrounding the conductor can be divided into materials for electrical insulation and sheath materials, which are mainly intended to protect against external influences.

Cable with a concentric conductor intended as a neutral conductor.

Grounded metallic sheath to limit the electric field to the cable interior and/or to protect the cable from external electrical influences. NOTE: Metallic sheaths, foils, braidings, reinforcements and grounded concentric conductors can also serve as shields.

Capacitance is a measure of how well a signal is transmitted (undistorted). For example, a high capacitance can change the input signal in such a way that it is no longer recognized as original by the receiver at the other end of the line, resulting in error messages.

Company identification threads are inserted into the product to clearly identify the manufacturer. This is particularly necessary if there is no printing or no clear printing. Examples of identification threads: -Company identification thread VDE, company identification thread SEV, company identification thread UL, etc.

Fillers are integrated into the stranding structure as a core element or as a core replacement. Its purpose is to ensure that the rope is as round as possible by supporting the cores of the stranding composite as a beam.

1000 Gy = 1 kGy (s. Gy/Gray)

The bobbin winding machines are used to produce the plaited wire for braiding or D-winding from individual wires.

Coaxial cables with tinned copper braids as outer conductors have an attenuation 15-20% higher than bare braids when new, but show a much more stable attenuation behaviour. Coaxial cables with silver-plated copper braids have the same attenuation values when new as cables with bare braids. In their long-term behaviour, however, they are to be judged in the same way as cables with tinned braids.

A coaxial cable consists of a center conductor and the electrically conductive shielding sheath, the braid (second current path). The word coaxial indicates that the axis of the inner conductor coincides with the axis of the shielding sheath.

An assembly of a flexible cable or cord provided with a non-detachable plug and a non-detachable appliance socket intended for the connection of an electrical appliance to the power supply.

have a uniform diameter. The electrical properties of concentric cables can be finished within narrow tolerances, smallest wall thicknesses are possible!

Conductor concentrically enclosing one or more insulated conductors.

Concentric conductor intended for use as a neutral conductor.

Element of a multi-stranded conductor consisting of a group of concentric wires.

The coupling resistance is a parameter for evaluating shielding for cables. The coupling resistance is a measure of the quality of the shielding and is defined as the ratio of the voltage along the shield of the disturbed system to the current of the disturbing system. The magnitude and the frequency response of the coupling resistance depend mainly on the structure of the shielding. At DC and low frequencies, the transfer impedance is identical to the DC resistance of the shielding. At increasing frequencies, it behaves completely differently, depending on its nature. For shielded balanced cables, the shielding effectiveness can only be reasonably determined by measurement. There are several different measurement methods, which differ in the frequency range to be measured.

At the insulation surface, foreign layers are evaporated by oxidation. The surface oxidation of the plastic increases the wettability and adhesion for paints. The corona treatment differs from the related electrical short circuit in that the discharge spark is extinguished very quickly after it is generated. This limitation enables the spatially uniform distribution of the discharge over the entire discharge electrode, prevents local overheating and damage to the cable insulation. The cables are usually only exposed to the discharge for 1/100 – 1/10 seconds. Even very thin cable insulation is only modified on the surface. Oxygen enrichment is only detectable down to a depth of approx. 5 nm (=8 atomic layers). Background: Cable insulation must have a surface energy of at least 38 nM/m to ensure the required ink adhesion. Polyvinyl chloride with 39 nM/m meets this requirement, polyethylene with 30 nM/m has poor wettability and is also non-polar. In principle, a corona pre-treatment must be carried out when printing on polyolefins. This measure ensures that the ink is not repelled from the material. The group of polyolefins includes all PE, PP, TPE-O.

A creepage path is formed by the progressive formation of conductive paths on the surface of a solid insulating material. It is caused by the effect of electrical stress and electrolytic contamination on the surface (see also CTI).

Electrolytically produced conductor material with a degree of purity of 99.9%, symbol Cu. Special form: OF Cu

The K-value is a measurement of the average degree of polymerization. (Average length of the PVC molecules). A higher K-value means longer PVC molecules. The higher the K-value, i.e. the larger the PVC molecules, the better the mechanical properties of the cable, but the more difficult it is to process. Generally, a K-value of 70 or 65 is used, which represents a good compromise between physical properties and still satisfactory processing properties.

Substances that interfere with paint wetting: LABS-/PWIS-free: These are terms that are mainly used in the automotive sector. The presence of certain substances (e.g. silicone oil) leads to unwanted cratering in the paint when painting vehicle bodies. If traces of silicone on operating materials (tools) cause the paint to adhere poorly or not at all to the new cars, this is referred to as paint wetting interference and craters are formed in the paint film. If a closed paint film is formed, the material is free of paint-wetting-disturbing substances (= LABS- or PWIS-free); nothing disturbs the smooth production flow of a production line more than stopping conveyor belts. This term can therefore be found prominently in almost all operating equipment regulations of the automobile manufacturers. paint wetting impairment substances (abbreviation LABS).

Tinned enamelled wires are usually insulated with PUR lacquer. The advantage of enamelled wires is the low wall thickness of the following insulation.

Stranded conductor in which the individual wires are arranged helically in one or more separate concentric layers with generally alternating lay directions.

If protective sheaths of underground cables are damaged, water can penetrate the cables. Due to the spreading of the water in the longitudinal direction of the cable, large stretches of cable can become unusable. To avoid this, swellable materials are introduced into the stranding compound and under the sheathing, which swell when they come into contact with water. As a rule, swelling powder or petrojelli are used as swelling materials.

s. Paint wetting impairment substances

Conductive part of an electrical cable, consisting of one or more individual wires.

(concentric conductor): unit consisting of several individual wires, all arranged helically and in uniform layers. The lay directions of successive wire layers are either alternating or constant. The lay lengths of the individual layers can be different or the same.

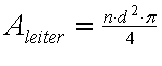

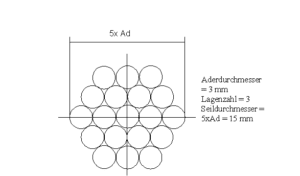

Value calculated from the conductor resistance and a specified specific conductance (e.g. 58.5 Fm/mm² DIN 72551 T6) / conductor… Conductor cross section / d… Diameter of the single wire / n… Number of single wires

Conductive layers are used to reduce microphony stresses caused by internal cable movements (friction between plastic and conductive materials). For this purpose, a thin, easily removable layer of conductive plastic is applied to the insulation (extrusion: firmly overmoulded with talc). This layer is then mechanically and thus electrically connected to the D or C shield.

Unit consisting of conductor, insulation and, if necessary, sheath, screen and jacket.

The line tender is an alternative to the trailing line device. Suitable for travel speeds up to 300 m/min – gentle cable routing – low space requirement – no cable sag – only half the cable lengths are required. Fields of application: Trolley power supply, rack stacking equipment, container cranes, etc. In addition to electrical cables, hoses (water, compressed air, oxygen, fuel gases, etc.) can also be laid on. Lines up to 1000 V

Cable trolleys are used as power supply systems for mobile consumers for moving flexible power and control cables. The advantage of cable trolleys is that, in addition to the energy supply, a large number of control cables and optical fibres can be carried. At the same time, hoses for gaseous and liquid media can also be connected. Fields of application: Trolley power supply, rack stacking equipment, container cranes, ports, steel mills, open pit mining areas, theatres, playhouses, etc. In addition to electrical cables, hoses (water, compressed air, oxygen, fuel gases, etc.) can also be laid on.

The liquidus temperature is the limit temperature at which the solder melts during soldering. Temperatures /= 450 degrees = brazing.

Unit consisting of several individual wires, all arranged helically in the same lay direction and lay length.

Stranded conductor, the individual wires of which are arranged in a helix according to the random principle with the same direction and lay length.

Lacquer-bonded strands are generally used for flat ribbon cables, as they are extremely compact. Good fabrication possible, better compliance with manufacturing tolerances.

Intended use usually for medical cables. Lahn strands consist of polyester threads with flattened copper: – highly flexible – high tensile strength.

Abbreviation for “Local Operating Network – LON, also called LONWORKS®, is a universal automation network developed by Echelon Corporation, Palo Alto, USA. Today it is used worldwide in building and industrial automation. In a LON network (similar to the EIB), tens of thousands of sensors and actuators can be linked to form an integrated building automation system.

an insulated cable laid on poles. Mostly used for the transmission of messages and sometimes also for the supply of electrical energy. Aerial cables are mainly used as telephone lines to peripheral areas or for construction sites or similar temporary facilities.

Outer insulating sheath of a cable with one or more shielded or unshielded cores.

Cable that has more than one core.

A stranded conductor consisting of a number of groups of wires arranged in one or more helical layers, each group being either twisted or stranded.

A sheath produced by the simultaneous extrusion of two or more layers of compatible materials which are firmly and inseparably bonded together.

Three-core cable with one concentric conductor provided as neutral.

Mega Hertz = 1 million vibrations per second

For example, if flexible PVC is in contact with other substances, especially paints and plastics, a plasticiser will migrate if it is compatible with the substance in contact. In case of incompatibility, the plasticizer is not accepted and migration cannot occur. Plasticizer migration is temperature and pressure dependent.

Thermoplastic polyurethanes based on polyester, without additional microbial protection, are subject to the risk of being degraded by microbial attack during prolonged exposure. Moisture combined with heat (e.g. in nutrient-rich environments such as grass, foliage, agriculture, etc.) can accelerate this process. In such environments, microorganisms multiply very quickly. The enzymes released by them cause a cleavage of the ester bonds and a destruction of the plastic part. In this case, a punctual infestation can be observed at first, in contrast to the hydrolytic degradation, which takes place on the entire surface. See also saponification number. Polyether-based polyurethanes are largely resistant to decomposition by microbial attack, but have poorer mechanical properties than comparable polyester polyurethanes.

Military Specifications, Military Standard (USA) English: Military Specification, Military Standard (USA)

Insulation consisting of a compressed mineral powder.

The modem (acronym or portmanteau formed from modulator and demodulator, hence modem) is used to exchange digital signals over long transmission distances between two digital terminals. The transmitting modem modulates a digital electrical signal (as a result of voltage changes) onto a carrier frequency in the high-frequency range, and the receiving modem recovers the original information by demodulating it into an analogue electrical signal (as a result of amplitude fluctuations). Modems of the newer DSL standard work with higher carrier frequencies and larger bandwidths on the telephone line than the models according to the traditional standard (“narrowband”).

Molecular mass, also molecular mass, formerly molecular weight, is the sum of the atomic masses of all atoms in a molecule. Mechanical strength, solubility and elongation depend (among other things) on the molecular weight.

Cable reels with motor drive are used as power supply systems for mobile consumers for the automatic winding of flexible power and control cables. Fields of application: Ports, steel mills, open pit mining areas, theatres, playhouses, etc. The drums are designed in spiral or cylindrical winding. The cable reels comply with VDE and UVV regulations. The cable outlet is horizontal or vertical. The cable reels are manufactured with different drives due to the requirements. High voltage lines up to 20 kV (with and without FO) can be accommodated.

The rodent guard is used to protect indoor and outdoor cables against browsing by rodents. It applies equally to electrical cables, coaxial cables and optical fibres. There are metallic and non-metallic protective designs. In the case of metallic rodent protection, the cable is encased by a metallic sheath in the form of a layered jacket. Non-metallic rodent protection is achieved, for example, by nylon or polyester coating of the cable or glass roving fibres under the sheath.

The mutual influence of signals in parallel running conductors by electromagnetic couplings. In multi-pair communication cables, the field effect of the signal transmission of one pair induces an interference signal in the neighbouring pair. This interference signal is frequency-dependent and becomes larger with increasing frequency. The difference between the wanted signal and the interference signal measurable on the adjacent pair is called near-end crosstalk attenuation (NEXT).

The rated voltage of a cable is the voltage to which the construction and testing of a cable is related with regard to electrical testing. U0: RMS value of the voltage between a phase conductor and earth. U: RMS value of the voltage between two outer conductors of a multi- or multicore cable or a system of single-core cables in a three-phase system.

see crosstalk attenuation

Process for optimizing the surface properties. The surface properties can be functional protection (protection against oxidation, protection against the influence of sea water, protection against environmental influences [e.g. when used in subtropical and tropical areas], certain resistance to acids, oils and alkalis, soldering aid, etc.) as well as decorative protection (colour, gloss level, possibly pattern, etc.). A combination of both is also possible. In most cases, this procedure involves several processes to achieve the desired result.

The surface resistance (also called leakage resistance) is the resistance at the surface of a test specimen. It is the electrical resistance to the flow of current between two electrodes placed on the surface of an insulator. The surface resistivity (surface resistance according to (ISO 93) is the surface resistance with a square test area, i.e. the length and spacing of the electrodes are the same. Its size depends not only on the insulating material, but also on the humidity, impurities on the surface and the measuring arrangement. A standardised arrangement must therefore be used for measurement. In particular, it is unavoidable that when measuring the surface resistance, the contact resistance is also recorded to an indeterminable extent and the measurement results can therefore not be transferred to another geometry. The unit of surface resistivity and surface resistivity is the ohm (1 Ω = 1 VA-1).

Copper with a purity content of 99.5%.

Characters: Ω. Unit of measurement for electrical resistance. Ohm’s law states that the electric current (amperes) is directly proportional to the voltage (volts) and inversely proportional to the resistance (ohms). Amps = Volts/Ohms.

High-voltage power lines for neon tubes, spark plugs and X-ray tubes produce ozone due to high electric field strengths. This attacks the insulation, especially in the case of additional mechanical stress. (Cracking). Ozone is the compound of three oxygen atoms (O³). It is formed from the oxygen present in the air under the influence of high-energy UV radiation. Due to its structure, ozone is very reactive and reacts easily with organic substances. This can be prevented by using ozone-resistant materials. EPDM or butyl rubber, for example, have good to very good ozone resistance.

Polyamides are formed by polycondensation of aminocarboxylic acids or diamines with dicarboxylic acids.

Polyethylene is a thermoplastic produced by polymerization of ethene [CH2=CH2] with the simplified chain structure formula. Polyethylene belongs to the group of polyolefins. Polyvinyls, e.g. polyvinyl chloride, are formed by substituting hydrogen. Polyethylene is manufactured on the basis of ethylene gas. Very low water absorption. Good electrical and dielectric properties.

The passage of a gas through a specimen is called permeation. It takes place in three steps: dissolution of the gas in the test specimen / diffusion of the dissolved gas through the test specimen / evaporation of the gas from the test specimen.

Abbreviation for the plastic polyethylene terephthalate. This plastic has a very universal property profile. Very good electrical properties and thermal behaviour, very good mechanical strength. Another significant advantage is the tightness against plasticizer migration.

Creamy material (petroleum jelly) obtained from petroleum for use in longitudinally waterproof cables.

Polyimides are polycondensation products of tetrabasic aromatic acids with aromatic diamines.

Here, macromolecules are attached to each other by mutual addition of reactive groups.

Polyethylene terephalates are linear saturated polyesters (thermoplastic) with high stress cracking resistance, resistant to water absorption.

The chaining together of monomers with the elimination of a by-product. Various monomers are linked together via reactive end groups with the elimination of water or ammonia.

Linking of monomers without splitting off by-products. The monomeric, gaseous or liquid starting products attach themselves to each other by splitting unsaturated double bonds to form filament molecules.

Number of monomers that make up a macromolecule.

Polypropylene, like polyethylene, belongs to the group of polyolefins. It is produced by polymerizing propene (propylene).

Conductor with non-circular cross-section.

The test voltage is the voltage value with which a line can be tested without changing the insulation properties. The test voltage is usually set 3 – 5 times as high as the later nominal voltage.

Polytetrafluoroethylene PTFE is a high temperature plastic and is not attacked by solvents or other aggressive chemicals. It shows no change after contact with most chemicals. Its surface is so smooth and slippery that hardly any foreign substance adheres to it. Moisture and UV radiation do not cause volume changes or weathering/brittleness. Tetrafluoroethylene is obtained by pyrolysis of difluorochloromethane.

Polytetrafluoroethylene / perfluoroethylenepropylene are insulating materials that have exceptionally good electrical, thermal, chemical and mechanical properties. Continuous temperatures of up to 205 degrees and operating temperatures of up to minus 90 degrees enable a wide range of applications. Fluorocarbon resins are practically resistant to all chemicals, especially strong acids and bases, solvents and hydrocarbon compounds such as those found in fuels. FEP and PTFE are flame retardant and can be considered practically non-flammable. The material properties are not affected by sunlight, UV rays and sea water.

Thermoplastic polyurethanes TPU are high performance materials with a unique combination of very useful properties. PUR cables are weather-resistant in all climatic zones. Yellowing of light colours under the influence of sunlight is possible, but does not affect the serviceability of the cable. For outdoor use and buried cables with TPU sheathing, polyether TPU is preferable in any case. If a higher UV protection is required for light coat colours, the material can be provided with a UV protection stabiliser concentrate.

Polyvinyl chloride is an amorphous thermoplastic. PVC is hard and brittle and only becomes soft, malleable and suitable for technical applications by the addition of plasticisers and stabilisers (optimum price-performance ratio among plastics).

Polyvinylidene fluoride: By reacting trichloroethylene with hydrogen fluoride and then reacting it with zinc, the 1,1-difluoroethylene can be obtained. This is polymerized to polyvinylidene fluoride.

English for paint wetting inhibitors see also LABS

controlled combustion under oxygen exclusion

Tape placed under the sheath or in the interstices of a conductor to prevent water spreading along the cable under the sheath or through the conductor, for example if the sheath has been damaged or the cable layers up to the conductor have been damaged.

Mass placed under the sheath or in the interstices of a conductor to prevent water spreading along the cable under the sheath or through the conductor, for example if the sheath has been damaged or the cable layers up to the conductor have been damaged.

Powder placed under the sheath or in the interstices of a conductor to prevent water spreading along the cable under the sheath or through the conductor, for example if the sheath has been damaged or the cable layers up to the conductor have been damaged.

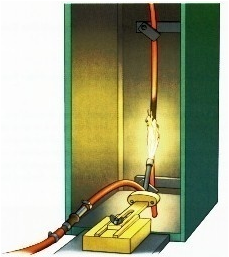

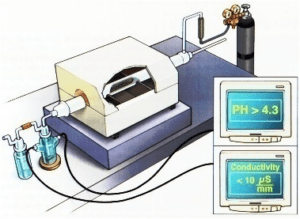

Smoke density – IEC 61034-1 / CENELEC HD 606: An important property in fire behaviour is the smoke emission of a material. The plastics used in cable technology are by nature strong smoke generators. This property can only be reduced with appropriate additives. The smoke is measured by means of the 3 m cube test according to IEC 61034-1. according to CENELEC HD 606. In a cube-shaped room with a photometric system with a light source (100 W) and a selenium photocell. A recorder connected to the photocell registers the light attenuation caused by the burning of the samples.

A conductor or single core cable which is laid in parallel with a cable or cable circuit and is itself part of a closed circuit in which induced currents can flow, the magnetic field of which is opposite to the field produced by the current in the conductor/cable.

Irregularities in the line and mismatches lead to a reflection of part of the transmitted energy. This results in a returning partial wave which depends on the size of the disturbance and causes a reduction in the useful power and transmission quality.

Resistin is a copper-manganese-iron alloy. It is an electrical resistance material.

Abbreviation for Radio Guide Utility. Military term for coaxial cable.

Ring printing is used to clearly identify the cores in a cable. The colour code is defined either by DIN 47100, or by a customer-specific code.

Restriction of (the use of certain) Hazardous Substances. RoHS regulates the use of hazardous substances in equipment and components and is anchored in EC Directive 2002/95/EC.

X-ray cables are flexible connecting leads with rubber insulation. The individual cores are embedded in a common rubber insulation. A layer of natural rubber is applied to this rubber cover as the main insulation. Graphic textile bands are applied to the braid.

In the case of metallic cables, return loss is the ratio of the energy fed into the cable to the energy scattered back. Such backscattering occurs due to inhomogeneities within the cable or in the RF connector. Part of the signal energy is reflected and propagates in the opposite direction in the cable. This signal portion is placed in relation to the signal level fed in. The ratio is the return loss, which is expressed in dB (decibels) and is directly related to the voltage standing wave ratio (VSWR).

Society of Automotive Engineers, American Standardization Institute of Transportation Technology, specifically a standard for designating the viscosity of lubricating oil.

Physical foaming can be achieved by adding nitrogen during the extrusion process. In physical foaming, a separate layer of Low Density PE (LDPE), Middle Density PE (MDPE) or High Density PE (HDPE) is extruded through an auxiliary extruder, depending on the desired properties. The maximum degree of foaming in physical foaming is 70 %.

Chemical foaming involves the addition of kicker PE. The KF melt is foamed in the extruder barrel. The protective foam layer (foam skin) is created during chemical foaming as a result of the process. It should be noted that in chemical foaming, the degree of foaming is limited. The degree of foaming itself can only be influenced within a very small range. The “influence window” is approx. 5 pF and can only be influenced by machine parameters such as extruder temperature and cooling trough temperature.

Conductive sheathing of one or more cores for protection against electromagnetic or electrostatic interference.

In order to be able to measure the effectiveness of this shielding, measuring methods were developed and a corresponding unit of measurement was introduced. This measurement is called shielding effectiveness and has the unit dB (decibel). This unit of measurement describes the ratio of voltages and currents to each other. To get an order of magnitude of the power ratios, it should be mentioned here that a shielding value of 30 dB means that the 1000th part of the power transported in a line is radiated to the outside, at 50 dB only the 100000th part. The shielding becomes more difficult the higher the power becomes. Antenna cables must have a high degree of shielding so that the low voltage absorbed by the antenna is not overwhelmed by the interfering radiation. Transmitters must be shielded so that they do not radiate an interference field. Receivers so that they do not pick up any interference fields. The best results are achieved with closed shielding structures (wrapping with metallic foils and additional braiding). Highly shielded cables with connectors that are not matched to them destroy the entire shielding effectiveness.

Voltage to earth occurring at the screen of a cable with special screen connection when symmetrical load currents flow in the conductors; it is usually specified for the points of the cable length where the maximum value occurs (i.e. at the unearthed part of a basic section in the case of one-sided earthing and at a crossing point in the case of crossing out). If the voltages for the three phase conductors are different, the largest value is usually used.

Axial length of a complete turn of a cable assembly element.

Ratio of the lay length to the diameter of a superstructure element.

Left or right twist (S or Z twist) of a stranding of a line or conductor.

Impact strength describes the ability of a material to absorb impact energy without breaking. Impact strength is calculated as the ratio of impact energy to specimen cross-section (unit of measurement kJ/m²).

With the hose method, the vertical pressure component acts on the mandrel and not on the cable core. The actual coating process only takes place outside the injection mould. This method is used wherever a pressure effect on the conductor is undesirable or not permissible. (Easy to strip).

The sum of the DC resistances of 2 cores (outgoing and return line of a line circuit).

For the processing of the moulding compounds, the plastics processor needs the guarantee that they are always available in the same quality (rheology). The most important characteristic of a plastic moulding compound is the flowability of the melt, which should be as uniform as possible in a batch. The melt index indicates the mass of a thermoplastic melt in grams that is forced through a standardized nozzle within 10 minutes at a specified piston force and melt temperature.

Inclined cables are required as trailing cables with high-strength armoured braiding on, for example, mining machines in mining and heavy moving machines in industry.

The shear modulus (also slip modulus (G-modulus), shear modulus or torsion modulus) is a material constant that provides information about the linear elastic deformation of a component as a result of a shear force or shear stress. While the Shore hardness and the cold fracture temperature provide information about the stiffness at certain temperatures, the shear modulus (torsion) determines the flexible behaviour over this temperature.

Stranded conductor consisting of several profiled stranded conductors which are slightly insulated from each other.

Profile ladder, the cross-section of which corresponds approximately to a circular section.

Swiss Electrotechnical Association (Electrosuisse – Association for Electrical Engineering, Energy and Information Technology) / Certification body

Silicone rubber: Silicones are polymers based on polydiorganosiloxanes.

The propagation speed depends on the transmission medium and is lower than the speed of light. The reduction in speed is caused by a so-called shortening factor (NVP). The shortening factor for coaxial cable is 0.77, for twisted pair cable 0.6 and for FOC 0.67. This means that the signal propagation speed in coaxial cables is 77% of the speed of light, (correspondingly for TP cables and LwLs). For optical fibers, the propagation speed for different wavelengths is expressed in the group velocity.

A skin layer is required for very small core diameters to improve foam structure and adhesion. The outer skin layer protects the porous foam structure against penetration of moisture and other substances. The sensitive foam is protected by the skin against mechanical effects. The better resistance of the foam-skin core prevents a temporal change of the electrical properties due to the indentation of the braid, see also foaming chemical

Printing with a deflected, continuous ink jet makes it possible to mark, label or date a product without contact. The ink is fed to the print head under pressure. The ink arrives in a small cylindrical container, the so-called “CANON”, which is equipped with a piezo crystal and a nozzle. A jet is formed as the ink exits the nozzle. Shortly after exiting the nozzle, the ink jet is modulated to produce calibrated and equidistant droplets. Drops are collected in an extraction tube and returned to the ink circuit.

The volume resistivity is the electrical resistance of the material interior measured between two electrodes, related to the sample geometry.

The specific gravity, also called weight, is the ratio of the weight of a body to its volume or, in other words, the density of a body in relation to the density of water.

The die head consists of a heated head housing and a conically fitted quill. The extrudate is fed to the wire guide mandrel via the heart curve milled into the sleeve. The heart curve thus has the task of distributing the plastic melt evenly and with equal pressure onto the quill. The wire guide is conically fitted into the quill. The outer nozzle can be moved longitudinally by means of a nut in order to equalize the pressure (newer die heads). With the somewhat older spray heads, pressure compensation is achieved by moving the sleeve (changing the distance between the inner and outer nozzles). The head material is usually hardened steel. The material for the tools, either steel or steel with carbide insert.

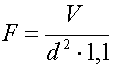

The capacity of a coil can be calculated with a formula: F = V /d² x 1.1 : F = capacity in m per ring, barrel or spool / V = usable volume in dm³ of ring, barrel or spool / d = mean outer diameter of the winding material

Layer stranding of 4 cores (worse capacitance values than DM quad). Low-capacity construction of four-person stranding units. The capacity between the pairs of a star quad is 1.5 times higher than that of a DM quad.

Insulated conductor in a power cable intended for the transmission of signals.

Multi-core cable for the transmission of control, regulation, measurement and display signals in electrical installations.

Current carrying capacity is defined as the current that a conductor can carry before either the insulation or the conductor itself melts. The heat generated by the flow of electric current through the conductor determines the current that the conductor can carry. There are a number of factors that limit the current carrying capacity of a conductor. The most important factors are: Conductor cross-section: The larger the cross-section, the greater the current-carrying capacity. Insulation: The temperature generated should never exceed the maximum permissible temperature of the insulating material. Number of conductors: The generation of heat is reduced to the extent that the number of individually insulated bundled conductors is increased.

SBR is a copolymer of butadiene and styrene and was the first commercially viable synthetic rubber. Properties: Good strength values, no resistance to solvents. Used e.g. as insulating material for telecommunication cables.

For high transmission rates not only an outer shield but especially a pair shield is used. In the signal receiver at the cable output, the partial signals of the two conductors are added together with their absolute value, resulting in the total signal. With this addition, the interference signals in the two individual conductors cancel each other out, so that only the useful signal is available. This makes the symmetrical transmission principle much less sensitive to external interference.

Talc: Mineral, slightly fatty natural product, used in powder form as a release agent. This results in easier stripping of the sheath. When extruding the sheath directly onto the cores, talc is used as a release agent. This is to prevent the cores from sticking to each other and to the sheath. Do not use talcum powder for medical and clean room lines and lines that must not contain substances that inhibit paint wetting.

If there is no temperature indication by printing, a temperature identification thread can be inserted as an alternative.

The fineness of fibres is determined by the fineness in the TEX system. According to this, a TEX is the fineness of a thread that has the mass of 1 gram when it is 1000 m long. For example: Polyester silk 7 Tex = 1000 m of silk weighs 7 grams.

Additives can be added to ensure the heat resistance of an insulation material.

Bedding material whose thermal properties are selected to facilitate the dissipation of heat from the cables.

Temperature difference between the inner and outer surface of a cable assembly divided by the heat flux passing through it.

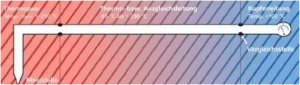

Cable with conductors of the same type as the thermocouple, that the latter extends to the measuring point and has the same thermoelectric properties within the whole applicable temperature range of the cable.

Cables with conductors that differ in material or properties from those of the thermocouple, but have such thermoelectric properties that the resulting error for a given temperature range is within specified limits.

In a temperature measuring device, thermocouple and compensating cables serve as the electrical connection between the open ends of a thermocouple and the reference junction.

In many cases, the thermoelectric or compensating cables are also routed to the measuring instrument.

Cable with conductors of the same type as the thermocouple, extending it to the measuring point and having the same thermoelectric properties within the whole applicable temperature range of the cable.

Highly polymeric materials in which there is a strong dependence of viscosity on temperature due to a mostly linear chain structure of the macromolecules. The group of thermoplastics is characterised by the fact that these plastics melt when the temperature is increased after the softening point has been exceeded, can be hot-formed and solidify again after cooling. The process can be repeated as often as required. In contrast to thermosets, no chemical reaction takes place during processing. Important thermoplastics include polyamides, polystyrenes and polyethylenes.

Printing with a deflected continuous ink jet makes it possible to mark, label or date a product without contact. An ink jet exits the print head through a nozzle. This beam is modulated by a piezoelectric transducer located behind the nozzle, so that a uniform decay (Rayleigh’s drop decay) into individual drops is achieved. The drops formed in this way are now electrostatically charged to a greater or lesser extent via a charging electrode. The droplets, which travel at speeds of 10 to 40 m/s, then pass through a larger deflection electrode, where they are deflected laterally, depending on their specific electrical charge. Depending on the type of device, the charged or uncharged drops now reach the cable. Unused drops are already collected at the print head and fed back into the ink circuit. The width of the line depends on the distance of the nozzle to the cable, whereby a higher distance reduces the resolution. The characters that are applied by a print head are called text. The text can exist as letters and numbers and different alphabets and different fonts or as logos and drawings. Each text created is saved, and can be printed or modified as needed.

Wire or rope whose primary function is to support a cable (the cable’s own weight), e.g. in an overhead line, and which may be arranged separately from the cable or integrated into the cable.

This cable connects the transceiver to the station interface (controller) on the Ethernet. It is limited to a length of 50 m. The cable impedance is 78 ohms.

The transceiver is the active component of an Ethernet LAN for connecting terminal devices to the electrical bus cable with functions for collision detection and signal adaptation. The word transceiver is a combination word of transmitter and receiver. It performs monitoring, forwarding, receiving and interference functions.

Thin layer to prevent mutual damaging influences between different construction elements of a cable, for example between conductor and insulation or insulation and sheath.

Liquid agent which is dripped onto the cores during extrusion and thus serves as a separating layer/liquid between the core insulation and the sheath. The use of release agents is intended to prevent the cores from sticking to each other and to the sheath.

A triaxial cable is a special form of coaxial cable that consists of three concentric conductors. These are separated from each other by a dielectric and a shield. Application areas are video technology and electrical measurement technology. In electrical measurement technology, currents in the femtoampere range can be measured with a suitable setup using triaxial cables. Due to the higher manufacturing costs, the cables are more expensive than coaxial cables.

Trunk cables are the main supply cables in broadband systems. These are coaxially constructed high-frequency cables that go from the head-end station to the customer connections. These coaxial cables have a diameter of one to two centimeters. The outer layer forms a solid plastic coating, under which there is a layer of aluminium. The power supply for the active components can be used within this aluminium sheathing. This allows the number of required stable supplies to be reduced to the feed points.

UL = Underwriters Laboratories – standards body in the USA / UR: Underwriters Laboratories Recognized – identification mark that can be affixed to products recognized by UL that comply with UL standards. cUR = Identification mark that can be applied to products that comply with CSA standards but whose testing and approval are handled by UL. Approvals are granted after testing cable samples at UL. Regular testing by UL inspectors ensures compliance with standards. As a service centre for UL in Europe, DEMKO is responsible for approvals, tests, etc. cUR Mark: UL has entered into a mutual recognition agreement with CSA. As a result, CSA approvals may be issued by UL and inspections for CSA are performed by UL. If a cable or wire complies with the CSA standard and approval has been granted, the product may be marked with cUR (Recognized Product for CSA).

The responsible manufacturer must label his product in such a way that the product can be clearly attributed to the manufacturer and the place of manufacture. Two methods are accepted for company identification: 1. manufacturer’s identification thread / 2. surface printing

Braided sheath of metallic or non-metallic material.

same stranding direction of all layers

Concentric stranding of successive layers with uniform twist direction and same twist length.

PUR generally has good UV resistance. Among the different PUR grades, PUR FHF (flame retardant halogen free) has the better resistance. PUR FHF dyed black represents the most optimal of all UV-resistant options in the PUR sector.

Approvals are granted after testing cable samples. Regular testing by VDE inspectors ensures compliance with the standards. Products which comply with the standard of the approval may be marked with the VDE symbol in accordance with the approval. The inspection of production sites, product controls and regular production monitoring is a prerequisite for maintaining the approval.

Stranded conductor in which the spaces between the individual wires have been reduced by mechanical pressing or drawing or by a suitable choice of profile or arrangement of the wires.

Helical stranding makes the stranding element to be stranded shorter. The elements to be stranded must therefore be longer than the subsequent cable by the extension factor.

Ratio of active power to reactive power for sinusoidal voltage. The dissipation factor depends on temperature, capacitance and frequency.

Radiation crosslinking is a practiced method for optimizing thermally stressable cables and conductors. Crosslinking specifically improves the following properties of insulation and cable sheaths such as higher operating temperature

– resistance to weld spatter

– improved tensile strength

– improved resistance to alternating bending

– improved oil resistance

– improved ageing resistance.

In irradiation technology, the irradiation dose, i.e. the radiation energy absorbed per unit mass, primarily determines the changes in the properties of the irradiated product.

Insulation consisting of a thermoplastic or a copolymer or a composite of one of these materials, the molecular structure of which has been modified by a chemical reaction such as crosslinking or vulcanisation and/or by a physical process such as irradiation.

In order to assess the resistance to microorganisms, the saponification value was determined. Absolute resistance to the phenomenon of microorganism attack is valid for saponification numbers VZ 200. Definition of saponification number according to DIN VDE 0472 Part 704: The saponification number is the amount of potassium hydroxide in mg required for the saponification of 1 g of the sample to be tested. Abbr. VZ

Stranding is an operation in which a number of stranding elements are joined together by winding them around a common axis. A mutual torsion is therefore required to prevent the combined unit from falling apart again. Stranding elements can be: single cores – yarns / light wave conductors – metal wires / strands – metal segments. The stranding process is intended to facilitate the handling of the elements. People use terms like bendable and flexible. Bendability and flexibility are essentially determined by the strand pitch “S + Z” given in mm.

In the Langs lay stranding method, the stranding direction is constant in all stranding layers.

In the cross lay stranding method, the stranding direction is opposite from strand layer to strand layer.

Ratio of the lay length to the diameter of a superstructure element.

In the case of the basket stranding machine, the rotary movement is performed by the stranding basket. The necessary longitudinal movement is taken over by the trigger device. In the basket stranding machine, the stranding elements rotate in front of the stranding nipple.

Cavities between the stranding elements are undesirable, they increase the amount of material used in the following operations. This requirement to keep the strand diameters as small as possible is essentially achieved by the stranding nipple; often one stranding nipple is not enough. Materials for stranding nipples are: Ø Metals / Ø Ceramics / Ø Plastics.

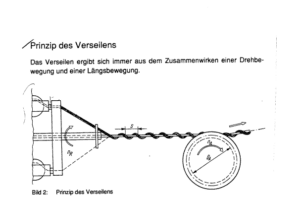

Stranding always results from the interaction of a rotary movement and a longitudinal movement. The rotary movement produces the rotation of the stranding elements around the stranding axis or around the core element. The longitudinal movement produces the forward movement of the core and strand elements, the trigger. The haul-off speed is calculated from the formula : V = S – N x 1000 / V= haul-off speed in m/min / S= strand pitch in mm / N= basket speed / min. In the case of a bundle of parallel stranding elements that is tied at both ends, the stranding elements on the outside of the bend are stretched and the stranding elements on the inside are compressed during bending. Since the stranding process causes the stranding elements to be located in sections on both the inner and outer sides, the expansions and compressions balance each other out. There is no deformation of the rope.

see lay length

Conductor consisting of several individual wires or strands, all or some of which are arranged in a helix. The cross-section of the stranded conductor can be circular or profiled.

Reverse rotation is used to avoid generating additional torsional stresses in the rope, i.e. no backspin is desired (low torsion). Backtwist refers to the twisting force that acts against the rope after stranding. It is caused by the torsional stress that the stranding elements experience during the entire operation. For some stranding elements this is quality-reducing. Backspin is generated wherever there is movement between the unwinding and rewinding devices.

Stranding with coil carriers rigidly attached to the basket is called stranding without reverse rotation.

Cables made of stranded insulated conductors or stranded single-core cables without a common sheath.

Stranded conductor, the individual wires of which are arranged in a helix according to the random principle with the same direction and lay length.

Metal coated conductor whose coating metal is tin.

Vierer in Metallfolie (ViMF) is the German term for an STP cable with two twisted pair wires shielded by a metal foil. The type of stranding can be a star quad or two twisted pairs of wires.

Unit of measurement for the actual power to be delivered to the application. The actual power is the product of the effective values of voltage and current consumption of the supplied device. P (VA) = U(V) x I (A).

Cross-linked polyethylene, see also cross-linking

Thermal expansion is the change in geometric dimensions (length, area, volume) of a body caused by a change in its temperature. The reversal of this process due to cooling is often referred to as heat shrinkage. Plastics, like all materials, are subject to a temperature-dependent, reversible change in length. It is given by the coefficient of linear thermal expansion a[1/K].

One of the most important properties of winding wires is their thermal resistance. It is expressed in heat resistance classes. Each of these heat resistance classes is assigned a continuous service temperature at which an insulating material guarantees a service life of 25000 operating hours.

The indentation depth is measured under the influence of heat (standardized method).

The insulating sheath of cores is tested for thermal shock by wrapping the cores around a defined dome and placing them in a heating cabinet at 150 degrees for one hour. After removal from the heating cabinet and cooling to room temperature, the test specimens must not show any visible cracks.

Heat stabilizers should prevent the decomposition of macromolecules under the influence of heat.

Water-treeing occurs when an electric field and water act simultaneously. Water-trees are tree-like structures growing in the direction of the field gradient, which cause irreversible damage to the cable dielectric, see also aging/chemical

Plasticizers influence the pliability, extensibility and modulus of elasticity. This means that it reduces the intermolecular forces so that the mobility of the molecules is increased.

Tear resistance is the resistance of a notched body to further tearing. The test is carried out on angle specimens which are provided with an incision on one side.

The impedance is a value that represents the ratio of electrical to magnetic waves of a data line. The characteristic impedance is of decisive importance for the compatibility of individual components of a data transmission system.

Metallic sheath with generally annular or helical corrugations.

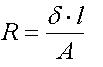

In electrical engineering, electrical resistance is a measure of the electrical voltage required to allow a given electrical current to flow through an electrical conductor. As a rule, R – probably derived from the Latin resistere for “to resist” (possibly from the English or French “resistance”) – is used as the formula symbol for electrical resistance. The resistance has the SI unit Ohm, its unit symbol is the capital omega (Ω). Related to the resistance is the specific electrical resistance (formula symbol ρ). This value is a temperature-dependent material constant, which allows a description of the resistance property independent of the geometric shape of the designed conductor. R = resistance [W] / p = specific resistance [W*mm²/m] / l = length of conductor [m] / A = cross-section [mm²]

Central-bonded solderable tinned CU wires bonded with a solderable varnish (flux). ZGL- SC Construction as for ZGL, but with steel cables. TC = Topcoat. Bare CU wires which are “hot-dip tinned”, i.e. drawn through a solder bath.

Braided tubular device applied to a cable, the diameter of which is reduced by pulling and with which the cable is frictionally gripped.

Special elements to absorb tensile forces in the sheathing area

Elastic materials can only be used without permanent deformation in the elastic (Hook’s) range, which is the only range in which the material returns to its original shape after being relieved of load. When overstretched beyond Hook’s range, residual stretch remains after unloading, and the longer it lasted, the greater the residual stretch.

Central Association of the Electrical Engineering Industry e.V Germany